Was Makeup A Must Tack?

Importance of Tack

Importance of Tack

Today, pressure-sensitive adhesives (PSAs) have great importance either in industry or in our everyday life. They are the main components of labels, tapes and decals. Their advantages such as:- Dry out form

- Instantaneous adhesion

- Easy to employ, and

- Large panel of adhesion capacities (force, substrates) are very of import indeed

All these properties are explained by a large variety of formulations, only involving only a few types of components, similar:

- Polymers – giving cohesion

- Tackifying resins, and

- Rheological additives (for instance alkane or wax)

The art of the formulator is based on the option of raw materials and additives, in club to find the best compromise between advantages and drawbacks given past each of these materials when they are blended and to meliorate the desired parameters and create synergies.

But, in social club to optimize a formulation (and the efforts needed to obtain information technology), information technology is necessary to apply specific tests for the evaluation of the particular property called TACK.

The word tack is often used simply has a variety of meanings. Let'south discuss the elusive nature of its definition and the importance of this concept to the adhesives manufacture.

What is Tack?

What is Tack?

The word "tack" is different others in the adhesives industry. Virtually of united states of america know what "tack" or "tackiness" refers to, but we have difficulty in defining it explicitly or in absolute units. The elusive nature of the word and the concept stems from the fact that "tack" results from a composite of several concrete observations, parameters, and concepts. This is non necessarily a serious flaw, since indeed this is the example.Tack is the property of an adhesive that allows it to adhere to another surface on immediate contact. It is the "stickiness" of the adhesive while in a fluid (e.g., paper cement) or semi-fluid (e.thou., pressure sensitive adhesive) state. At that place are two stages that must be considered with this concept.

- The first is the wetting stage where the tacky material must wet the substrate or a probe's surface - the most mutual probe existence the human pollex. This initial phase is controlled by concrete-chemical properties, such as critical surface tension, viscosity, adhesive thickness, etc.

- The 2d stage is that of debonding the probe from the surface, and here rheological properties of the adhesive come into play.

According to the ASTM standard, tack has been divers as the property that enables an agglutinative to form a bond of measurable strength with the surface of another fabric upon brief contact and under high pressure level. Implicit is that the adhesive separates cleanly from the surface, without whatsoever macroscopic residue.

One can hands understand that the tack property is greatly influenced by the experimental parameters. Information technology depends on:

- The nature of the PSA

- The adherend

- The pressure and,

- The time of contact

Moreover, because the response is a viscoelastic ane, the temperature and the rate of debonding play a key role in the strength measured.

In other words, tack is defined by the test used to measure it. So, information technology is very important to know what kind of tests are used, what kind of information is given and their limits.

Related standards are published by national groups such as ASTM, and also past professional associations like European Pressure Sensitive Manufacturers' Clan (EPSMA), or FINAT.

Normalized tests are well divers and require equipment that is easily available. They are a span betwixt laboratories, users, distributors, and all the other partners involved in this manufacture. Information technology is logical (and highly recommended) to apply these methods if they are related to your problem.

Measuring Tack

Measuring Tack

The word "tack" is unlike others in the adhesives manufacture. Most of united states of america know what "tack" or "tackiness" refers to, merely we have difficulty in defining information technology explicitly or in absolute units. The elusive nature of the discussion and the concept stems from the fact that "tack" results from a blended of several concrete observations, parameters, and concepts. This is non necessarily a serious flaw, since indeed this is the case.Tack is the property of an adhesive that allows it to attach to some other surface on firsthand contact. It is the "stickiness" of the agglutinative while in a fluid (e.one thousand., newspaper cement) or semi-fluid (due east.g., pressure sensitive adhesive) state. There are two stages that must be considered with this concept.

- The beginning is the wetting phase where the tacky material must wet the substrate or a probe's surface - the most common probe existence the human thumb. This initial stage is controlled by physical-chemical backdrop, such as critical surface tension, viscosity, agglutinative thickness, etc.

- The second stage is that of debonding the probe from the surface, and here rheological properties of the adhesive come into play.

According to the ASTM standard, tack has been defined as the holding that enables an adhesive to form a bail of measurable strength with the surface of another material upon brief contact and under high pressure. Implicit is that the adhesive separates cleanly from the surface, without any macroscopic residue.

Ane tin hands understand that the tack property is greatly influenced by the experimental parameters. It depends on:

- The nature of the PSA

- The adherend

- The pressure and,

- The time of contact

Moreover, because the response is a viscoelastic i, the temperature and the rate of debonding play a primal role in the force measured.

In other words, tack is divers by the test used to measure out it. So, information technology is very important to know what kind of tests are used, what kind of data is given and their limits.

Related standards are published by national groups such equally ASTM, and as well past professional person associations similar European Force per unit area Sensitive Manufacturers' Association (EPSMA), or FINAT.

Normalized tests are well defined and require equipment that is easily available. They are a bridge between laboratories, users, distributors, and all the other partners involved in this manufacture. It is logical (and highly recommended) to utilise these methods if they are related to your problem.

Methods to Exam Tack

Methods to Examination Tack

Tack tests are designed specific for the application. The results will heavily depend not only on the weather of the agglutinative & adherend, but also on the way contact & separation is achieved. Tack measurements are likewise dependent on the time during which the substrates were joined.Of course, such parameters are very awarding specific, and that is why many different tack tests have been constructed and are in use. The table below summarizes several common methods of measuring tack.

| Organization | Test Method | Common Name | Note |

| ASTM | D2979 | Probe Tack | |

| ASTM | D3121 | Rolling Ball Tack | Identical to PSTC 6 |

| TLMI | LIB 1 | Loop Tack | LIB1 uses a specially designed tester; |

| PSTC | 5 | Quick Stick | Similar to AFERA 4015 |

| PSTC | 6 | Rolling Ball Tack | Identical to ASTM3121 |

| FINAT | FTM | Loop Tack | Similar to TLMI methods except uses glass rather than stainless steel as the substrate |

| AFERA | 4015 | Quick Stick | Similar to PSTC 5 |

| ASTM - American Society of Testing and Materials | |||

Tack, therefore, is not a true physical holding of an adhesive, such as viscosity, modulus, or specific gravity. It is a blended property that has broad and somewhat qualitative meaning, but one that is very useful in exercise. Quantitative meaning tin can simply be defined through specific application.

Let's talk over each method in particular...

#1. Rolling Ball Tack Test

In this procedure, a rolling object (a steel ball according to this standard, but other geometries and materials are also possible) is placed at the pinnacle of an inclined track pursued by a horizontal, upward-facing agglutinative. The ball is rolling downwards, and the relevant measurement is the distance the brawl travels forth the adhesive tape.

This simple, but frequently used test is probably one of the oldest. Despite its simplicity, it gives a expert idea of the adhesive behavior and is readily understood. This distance is inversely proportional to tackiness: the greater the altitude, the less tacky the agglutinative.

But this test can but be applied equally an internal comparative test because at that place is no information about the adhesive surface or bulk parameters. And different attempts to summarize bibliographic data (using balls of different sizes, composition, texture) have not given (for instance) a good mechanical model, reliable measurement and adhesive backdrop.

Practically, the measurement needs to be performed several times to obtain average values and a meaning upshot.

For many adhesives, a wide range of results are obtained; moreover, the maximum prescribed distance in the standard is often lower than the experimental one. The method by itself is low cost and like shooting fish in a barrel to use just often needs to exist adapted to the parameters of the real system (temperature, tack capacity). Information technology is also a good quality control for tapes, for case.

| Advantages | Drawbacks | Applications |

|

|

|

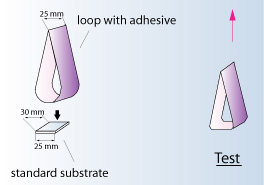

#2. Loop Tack Test

In this test, tape samples are round loops caught in the upper jaw of a tensile tester. This pear or teardrop is brought into contact with a horizontal surface (model or real system) for a short conventional time so peeled off.

Every bit for the rolling ball examination, variations near this scheme are possible for example shape of the substrate & pressure applied. The primary advantages of this examination are:

- It is easily and quickly performed

- Does non crave specific equipment (a standard tensile tester is sufficient), and

- The reproducibility is in most cases acceptable

When equipped with an environmental chamber, i can also vary contact conditions, and in this mode, study their influence. Merely drawbacks are originated from the method itself. Contact time and peel bending are difficult to reproduce, and the stiffness of the tape backing is also strongly influent.

In summary, the loop tack test is a good means of measuring the tack of labels or tapes when the applications are confined to the experimental weather.

| Advantages | Drawbacks | Applications |

|

|

|

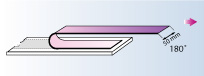

#iii. Peel Tack Test

Derived from the standard skin test (simply time and pressure of contact are lower), information technology can be compared with the previous test (but in this case, the operator itself puts the agglutinative on the adherend surface).

The equipment required is the same equally that for the loop tack test, except that a reproducible pressure must be applied. If it is slightly less quick to carry out, a ameliorate reproducibility is achieved because of a ameliorate control of contact conditions and pare angles. It actually becomes possible to compare peel measurements at dissimilar contact times & force per unit area and to extrapolate at naught fourth dimension of contact to obtain an "accented" value.

Withal, the stiffness of the backing is as well influent, and the results depend not only on agglutinative tackiness but also on the record modulus. To summarize, peel tack test can be interesting, but one can be far from a real tack test if pressure and time of contact are too high; as with other tests, one must be as near as possible to the usual conditions.

| Advantages | Drawbacks | Applications |

|

|

|

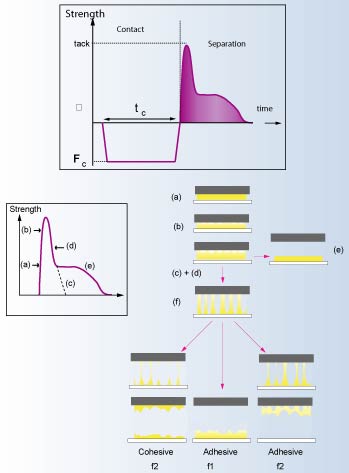

#iv. Probe Tack Test

The simplest equipment to evaluate tack backdrop is a pollex. Brought into contact with a slight pressure level and, after a short delay, pulled away from the adhesive, the sensation of tackiness felt by the operator can be reported on a scale of, by example, 0 (no tack) to 5 (very ambitious tack). But it is obvious that this method is not reproducible - each operator has his own appreciation, varying according to the solar day or his ain senses.

So, although more precise sensors and more than reproducible probes are preferred, the idea is the aforementioned. Mechanical probe tack testers bring a probe (ball or cylinder of diverse material) into contact at controlled rate and force per unit area, wait a given delay, and measure the force needed to pull away at a specified rate. Near systems let each private parameter involved in the bond germination to vary (the ASTM D2979-00 is related to the first experimental equipment, called "Polyken Probe Tack").

One can obtain this effigy, reporting the measured force during the experiment.

Information technology is very interesting to understand the phenomena observed during the separation betwixt a tacky adhesive and an adherend.

- The stress increases linearly with the probe displacement

- The stress slowly increases and is no longer linear, because a nucleation phenomenon occurs (bogeyman of voids at the interface)

- The force goes up to a maximum, when the nucleation stops

- Cavities start to abound perpendicular to the interface, involving a subtract of the stress; at this stage, the shape of the curve depends on the rheological properties of the adhesive and on interfacial interactions between the agglutinative and the probe; there are two possible ways for debonding to occur:

- Voids can grow until coalescence occurs: in this case the failure is adhesive and the stress decreases to goose egg

- Cavities can grow to reach a critical size, and fibrillation appears. Fibrils can lead to adhesive failure (f2) or cohesive failure (f1)

In this method, the experimental parameters are the same equally during a real bonding process:

- Contact pressure level

- Contact fourth dimension

- Temperature

- Rate of separation

- Probe used (shape, material), and

- Adhesive system (thickness, bankroll, roughness)

Although the results are more difficult to analyze, this method is a precious 1. The apply of a dynamometer gives loftier precision and the parameters (forces at different contact times, but also energies of debonding) can lead to a better understanding of the PSA behavior.

| Advantages | Drawbacks | Applications |

|

|

|

PSA Testing: Standard Tests When There Is No Standard

Talk to Edward Petrie where he will review the latest in testing, share of import testing parameters (joint design, speed of bond separation...). He volition also guide y'all on when & how to use specific tests to ensure a successful PSA bond.

Related Read: Explore the Test Methods to Mensurate Bear on Strength of Adhesive Joints »

Source: https://adhesives.specialchem.com/selection-guide/test-methods-to-evaluate-tack

Posted by: wellsuplits00.blogspot.com

0 Response to "Was Makeup A Must Tack?"

Post a Comment